Avery Dennison - Future Leader of the EVB space

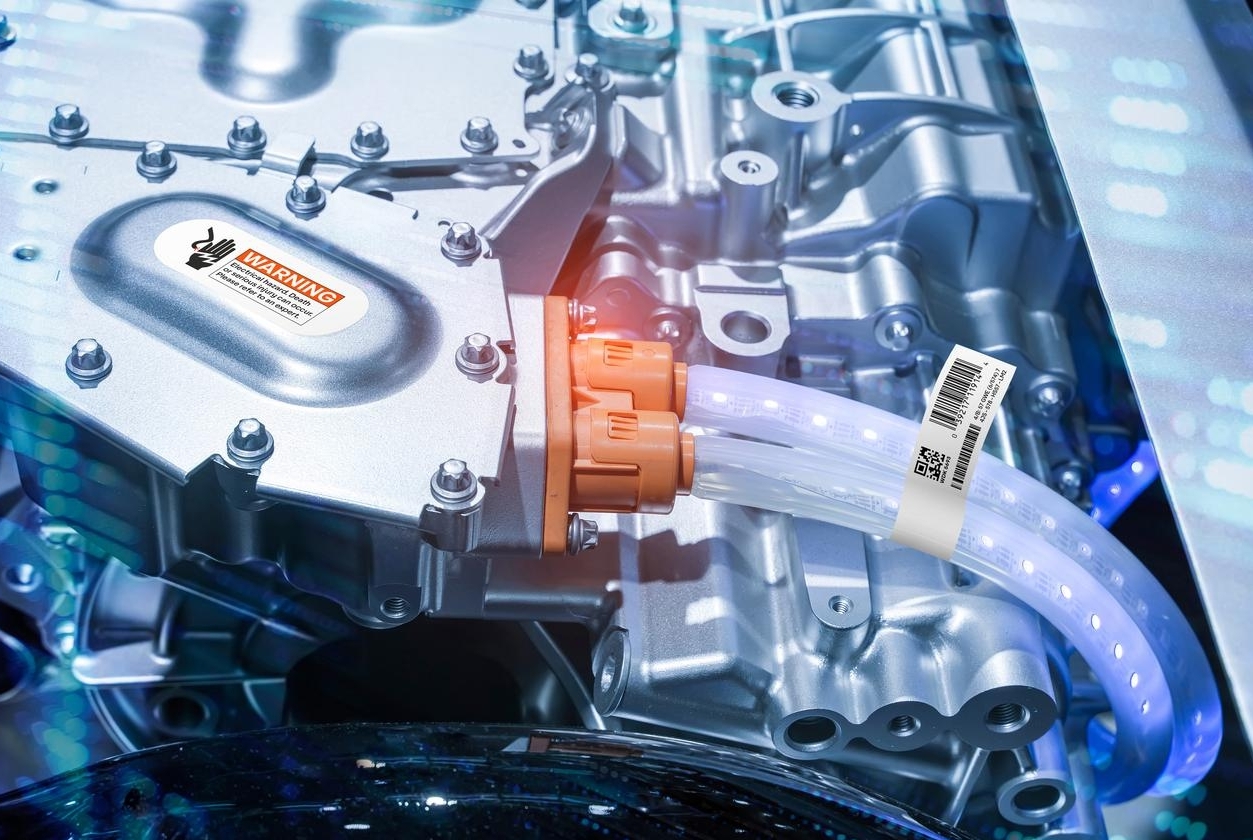

As a recognized leader in many key automotive areas, Avery Dennison develops innovative adhesive materials for automotive applications such as Electric Vehicle Batteries (EVBs).

Our materials meet manufacturer's requirements, optimize production efficiencies and enhance the driving experience and now that Electric Vehicles (EVs) are increasingly taking over the market, we’re entering an era of challenges wholly new to the industry.

It has been a decade and a half since Tesla introduced its first Roadster. ‘EVs are here to stay’ is a bit of an understatement. It’s no longer an evolution, but a revolution. More drivers are taking a pass on the internal combustion engine of days past in favor of electric motors powered by state-of-the-art battery packs. Indeed, in response to a variety of factors, including changing consumer tastes and progressive regulatory activities, OEMs are setting time-bound goals to be exclusively electric.

"We welcome a leadership role in helping the industry adapt to those challenges. "

With Electric Vehicle Batteries constantly evolving, we know how important cutting-edge adhesive solutions are. Electric vehicles are poised to take charge, putting EVB – and the 40 percent of overall vehicle cost it represents to OEMs, cell producers, pack integrators, functional material suppliers and converters alike – at the very heart of the revolution.

Avery Dennison automotive solutions

We have a long history in the automotive industry. Since the inception of our Performance Tapes business unit in the 1960s, our Automotive Portfolio has evolved with solutions for a wide range of applications — applications that have evolved with vehicles themselves.

We have worked (and continue to work) closely with OEMs, tier suppliers, and converters to understand engineering challenges, design requirements and growth opportunities and have collaborated with all of them to develop effective and reliable solutions.

As proud as we are of this history, we are even more excited about the industry’s future. It should come as no surprise then that we are staying in step with the industry as it undergoes this EV revolution. We welcome a leadership role in helping the industry adopt pressure-sensitive adhesive tapes in EV applications. Our EVB portfolio will grow over time, and change as the needs of the industry change now that we’re witnessing vehicle development that alters the very definition of the automobile.

Whether or not you are excited about the passage into history of the internal combustion engine, the fact remains the converting and tape industry is poised to grow. The EVB space is described as a wild west by many leading experts. It is causing disruption in the automotive industry, many sleepless nights, and engineers are working in areas that are completely new to them. There are no established methods, industrial practices, or even no shared standards yet. Luckily, you can count on Avery Dennison to provide the solutions you need, when you need them.

"We can serve everyone within the EVB industry"

The EVB industry

First off, we don’t design, produce or sell battery packs. We merely provide reliable, tailored and purposefully developed adhesive solutions fitted to a wide range of EVB use cases, including cell to cell bonding, compression pads, cell wrapping, electrical insulation, thermal runaway protection, and more. It puts Avery Dennison at the heart of the EV revolution, as our solutions are built on multiple pressure-sensitive adhesive technologies, engineered to make EVB solutions safer, more efficient, and easier to assemble.

Of course, somebody has to put the pack into the car. OEMs are looking to build both the modules and the packs themselves – it represents about 40 percent of the car value. Which is why they are building battery plants. Avery Dennison can help OEMs to tackle some of the most common challenges associated with electric vehicle batteries, as pressure-sensitive materials are suited for providing solutions for some of the most vexing challenges that have faced battery pack manufacturers as they have raced to improve their technology.

Meanwhile, the cell builders are building packs and modules too. In other words, there is vertical integration on both sides. We’re on both sides too.

Our solutions are appropriate for everyone in the EVB industry.

- OEMs

- joint ventures

- cell suppliers who are supplying the finished battery packs

- converters and suppliers of functional materials*

- converters and suppliers of functional components**

*Functional materials can include the die cut materials that are assembled with the cells into the modules/packs to provide protection from impact, heat, fire, explosion, electrical sparking, etc

**Functional components may be chiller plates, metal parts and other specific materials used for the proper (e.g. bound by regulations and quality assurance) assembly

Innovation and challenges in EVB

Avery Dennison Performance Tapes specializes in EVB pressure-sensitive adhesives that offer peace of mind – which has become an important factor. We see many design and material selection changes during project gestation; as the design changes to accommodate new demands, decisions are being made “on the fly”. This is a new and rapidly growing industry and there are no standard practices and designs established yet. In other words, everyone is doing their own thing, looking for “unique” solutions as their challenges are created by their choice of design and materials.

It’s a fast-growing industry, where productivity and more importantly quality assurance are critical. We can offer an understanding of how PSA tapes contribute to safety, performance, durability and manufacturability – from product requirements to the application methods. Because these applications all have varying requirements for factors such as dielectric strength, flame retardancy, bond strength and more. It doesn’t matter if you are a converter, a supplier or an OEM, there is a focus on differentiating features for specific benefits.

Whether you’re looking for EVB tapes to provide dimensional stability with easy release liners that help protect delicate materials during assembly, tapes that incorporate dielectric films for breakdown voltage and dielectric strength requirements, tapes that use acrylic- and silicone-based adhesives with flame-retardant properties, all of the above or anything that meets the ongoing dynamic of changing regulations, Avery Dennison offers a solution. Moreover, we can assist in meeting these challenges from a position that is uniquely flexible. In the expanding world of EVB and all its existing and future challenges, we have the expertise, the knowledge and the technology to offer that solution.

The Avery Dennison Toolbox

The Avery Dennison EV Battery portfolio includes a wide range of functional bonding and protection tapes, built on multiple pressure-sensitive adhesive technologies. These are engineered to make EVBs safer, more efficient, and easier to assemble. The portfolio can help you solve some of the most common challenges in battery design and construction, including reducing flammability, boosting dielectric strength, or optimizing design and assembly through functional tapes that can replace mechanical fastening methods while offering a thinner profile, lighter weight, repositionability and instant bond.

"We’re not here to sell you a portfolio of products. Instead, we're offering you solutions."

Specific, custom tailored solutions to meet the wide variety of needs and requirements, now and in the future. We take great pride in that customization, and in the ability to find and offer the right solution.

Whatever the challenge, inquiry or application, you can rely on Avery Dennison technology to offer the solution.