What is surface energy and how does it affect the choice of adhesive?

Surface energy is often mentioned in discussions of pressure-sensitive adhesives (PSAs), but what actually is it? In this article we’ll explain the reality of surface energy at a molecular level, why different materials have different surface energies, and what this means when you’re choosing a PSA that will adhere to them.

Demystifying the concept of surface energy

There are some concepts in physical science that are difficult or impossible to visualise in a way that aligns with our everyday experience – such as the four-dimensional nature of space-time, the property of nuclear spin, or how exactly perpendicular electric and magnetic fields can constitute a propagating light wave.

For anyone having to use these concepts to solve a problem, rather than trying to interpret their physical reality, it’s commonplace to accept the advice “Shut up and calculate”, famously used by David Mermin in reference to the Copenhagen interpretation of quantum mechanics.

And it’s tempting to take the same stance when it comes to surface energy – a rather mysterious quality that is associated with a surface. You can certainly get by with just accepting that some surfaces have high energy, others have low energy, and ‘do the maths’ to work out the consequences for the way they interact with other materials – with pressure-sensitive adhesives (PSAs) being of particular interest to us of course.

But to think about surface energy in this superficial way runs the risk of missing out on some useful insights into the way materials interact. So in this article we hope to demystify surface energy, and provide a way of thinking about this phenomenon that makes it more than a purely mathematical convenience. That in turn will help us understand why some surfaces readily adhere to substances applied to them, and others don’t – which has implications for tackling the more difficult adhesion challenges.

"Surface energy and surface tension"

Surface energy has the symbol γ, and applies to any solid or liquid substance. But when considering the interactions of liquids, the term surface tension (γ or σ) is more common – although it is equivalent both conceptually and mathematically.

Because the focus of an adhesive application is the (solid) surface that’s receiving the adhesive, at Avery Dennison we generally talk about surface energy, so that’s how we’ll refer to it in this article.

How does surface energy arise?

To start with, let’s begin with the observation that a substance in bulk is nearly always more thermodynamically favoured than the same substance broken into pieces. This is just as well, because otherwise everything in the universe would still be in the gas phase, and we wouldn’t be here to talk about it.

This idea of bulk materials being thermodynamically favoured can be imagined as a sort of potential energy. So just as a ball at the bottom of a hill has a lower energy than one at the top of a hill, a block of (say) glass has a lower energy than the same block broken into fragments.

The process of breaking a solid apart is in fact central to one of the key mathematical formulations of surface energy. Imagine cutting a solid block of material in half, and separating the two freshly-exposed surfaces. If the cutting process is done reversibly (i.e. infinitely slowly, so that everything remains in equilibrium and no heat is dissipated), then the energy expended in the whole process will equal the surface energy of the two new surfaces.

The only thing that has changed in this idealised scenario is that all the bonds that formerly spanned the now-separated surfaces have been broken – and the energy used to break all those bonds is now ‘contained’ in the two surfaces. This links through to a commonly cited definition of surface energy, albeit one that isn’t especially helpful for visualising what it is – the excess energy at the surface of a material compared with the bulk material.

But what does that ‘excess energy’ really mean at a molecular level? The answer is rather complex, because it depends on the nature of the interactions, and what happens to them when two surfaces are separated. To take a simple example, when two covalently-bonded atoms are separated, the electrons formerly interacting with both nuclei in a low-energy orbital between them must now interact just with one nucleus in a tighter, higher-energy orbital, so the energy of the whole system goes up.

A similar principle applies to the electrostatic forces that are at play in the surface interactions of PSAs, whether they involve ion–ion pairs or dipole–dipole interactions: the energy of the electrons involved goes up when the interactions are disrupted. ‘Surface energy’, therefore, really just adds together the raised energies of the electrons that contribute to external interactions on that surface – to put it another way, it’s a measure of their latent ‘desire’ to interact.

The ease of wetting a surface

One of the main uses of surface energy is to predict what will happen to a liquid when it comes into contact with a surface. Generally speaking:

- If a surface has high surface energy, then liquids will easily spread out over the surface, because that maximises the number of intermolecular interactions between them.

- If a surface has low surface energy, then liquids will tend to form droplets on the surface, because that maximises the intermolecular interactions within the liquid.

It therefore follows that forming a strong bond between an adhesive and a substrate is easier when the substrate has a high surface energy, because it is more easily ‘wetted’ by the liquid. Conversely, substrates with low surface energy are difficult to form adhesive bonds to, because the release of the surface energy on wetting may not be sufficient to overcome the cohesive forces within the liquid.

The role of substrate surface energy in ease of surface wetting. (A) A substrate with high surface energy will readily allow a liquid to spread out over it, providing complete coverage. (B) A substrate with a low surface energy will cause the liquid to ‘bead’ on the surface, resulting in incomplete coverage.

It’s worth pointing out that the properties of the adhesive are crucial here too, including its viscosity and surface energy. However, for practical applications adhesives need to have a fairly tightly defined viscosity, and their surface energy does not vary as much as substrates do (usually 36-39 dynes/cm or mJ/m2). So except in the more challenging cases, the focus is usually on the surface itself.

"Measuring surface energy"

There are several ways of measuring surface energy, but the easiest one to apply, and the most commonly used, is the contact angle method. This involves placing drops of several liquids with known surface energy on the substrate, and measuring the angles at the phase boundary using an instrument dedicated to the purpose. These results can be used to work out the surface energy of the substrate.

Values of surface energy are usually given in millijoules per metre squared (mJ/m2), but the numbers are exactly the same with the equivalent units of millinewtons per meter (mN/m) or dynes per centimetre (dyn/cm).

The surface energies of different materials

So what are the surface energies of the materials commonly encountered in adhesive applications?

- Metals, with their large number of free-roaming electrons in the ‘conduction band’, have the highest surface energies (700–1100 mJ/m2).

- Ceramics have high surface energies (200–500 mJ/m2) because of the abundance of highly polar oxygen–metal groups on the surface.

- Silica, silicates and glass have moderately high values (100–300 mJ/m2), albeit somewhat lower than ceramics, because of the relatively low polarity of the silicon–oxygen bond.

- Graphite, because of its within-layer conductivity due to its conduction electrons, has a moderately high surface energy (55–130 mJ/m2).

- Wood and paper contain oxygen-rich lignin polymers, but nevertheless have only moderate surface energies (40–55 mJ/m2), which depend substantially on the surface preparation, water content and porosity.

- Engineering polymers, like polymers in general, have fairly low surface energies (35–50 mJ/m2) because they contain a large proportion of non-polar bonds. However, engineering polymers usually contain some polar functionalities, which helps to raise their surface energies slightly.

- Hydrocarbon, fluorocarbon and silicone polymers have very low surface energies (18–40 mJ/m2) because of the very low polarity of the bonds present.

From this list, it becomes clear that surface energy is increased when the surface contains components with conduction electrons, polar bonds or ionic structures – which makes sense in terms of our earlier discussion about the molecular reality of surface energy. And it’s that knowledge that proves useful in PSA design.

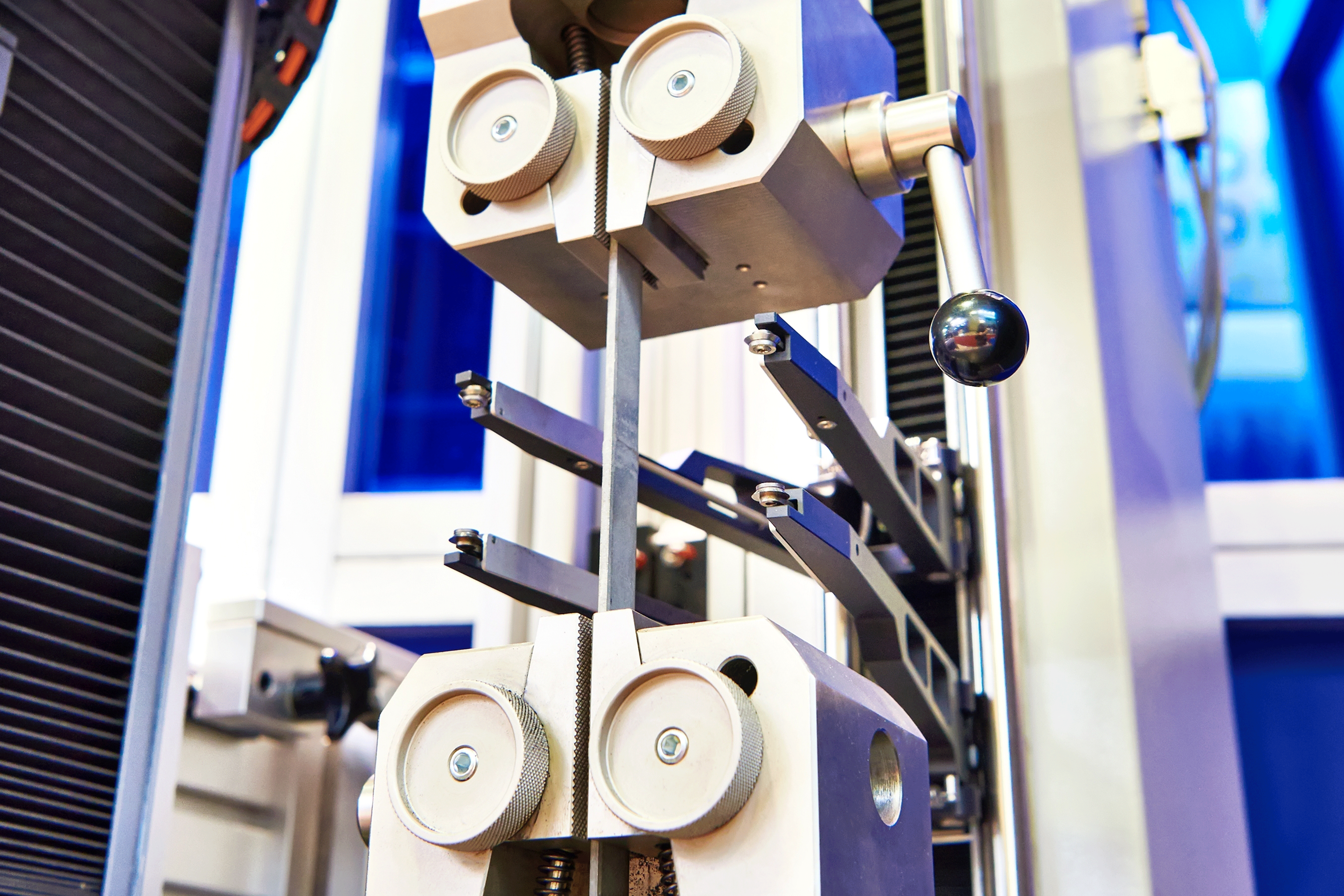

Caption When selecting a pressure-sensitive adhesive, consideration needs to be given to the surface energies of the laminating and mounting surfaces.

Conclusion

Although it’s tempting to treat surface energy as just a number, an understanding of how this phenomenon arises is helpful to inform our choice of PSAs for a particular application – particularly when it comes to surfaces with unusual characteristics requiring a tailored adhesive.

For example, we might need to raise the surface energy of a substrate by incorporating polar units, or select an adhesive with a less polar molecular structure to ensure it has sufficiently low surface energy. Every option will have its advantages and drawbacks, and that’s of course where it’s helpful to have a specialist on hand to help.

If you need advice on identifying the best PSA for your application, then please try our Product Selector, or talk directly to an Avery Dennison specialist at martin.dolezal@eu.averydennison.com.

Further reading

About the author

Martin Dolezal

Martin Dolezal is a seasoned marketing manager with a focus on automotive and energy storage within the Materials Group EMENA. He overesses the self-adhesive product portfolio catering to the evolving industries of automotive, energy storage, EVB, durables, and aerospace.

Martin joined Avery Dennison in 2009 as a technical sales specialist based in the Czech Republic, evolving into a leader of a technical sales organization in Eastern Europe, Mena, Russia. Since joining EU headquarters 2017 he has served in various manager roles, leading the charge in shaping the strategy and positioning for Avery Dennison’s paper and variable information (VI), special papers, and digital portfolios.

Prior to joining Avery Dennison, Martin worked for one of the largest converters in the Czech Republic developing automated labeling machinery for multinational B2B partners, which provides him with a customer-centric perspective that he brings to his role.

martin.dolezal@eu.averydennison.com

https://www.linkedin.com/in/martin-dolezal-84a10123/