Flammability and standard testing for EV batteries

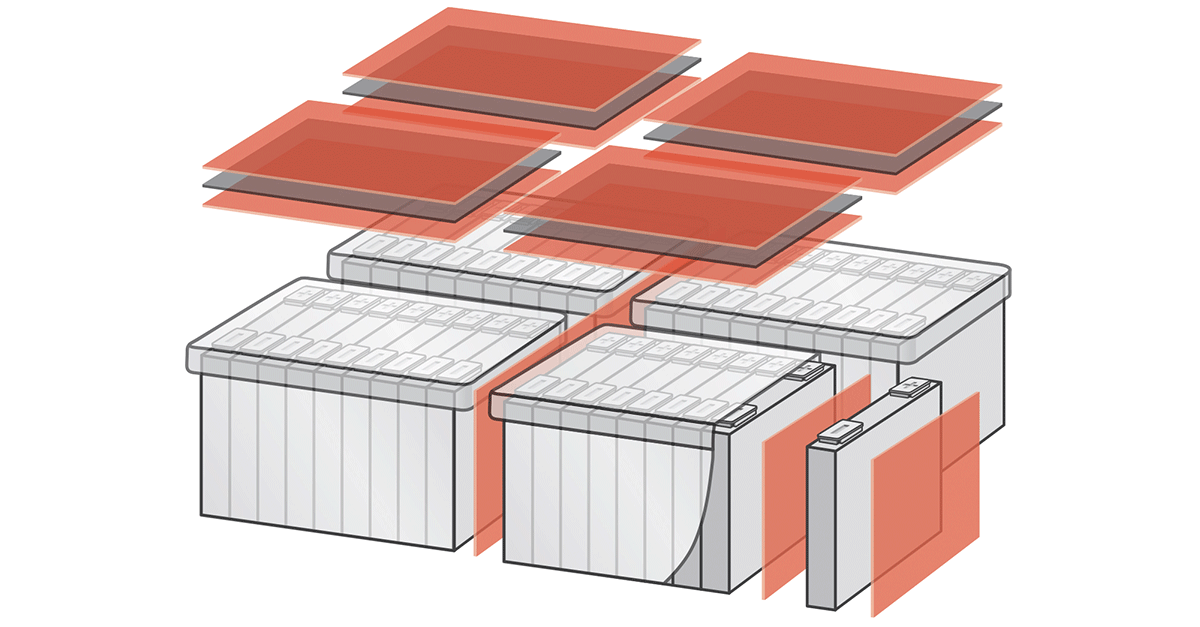

As a recognized leader in key automotive areas, Avery Dennison develops innovative adhesive materials for automotive applications that meet manufacturer's requirements, optimize production efficiencies and enhance the driving experience. We provide reliable, tailored and purposefully developed adhesive solutions fitted to a wide range of EV battery use cases, including cell-to-cell bonding, compression pads, cell wrapping, electrical insulation, labeling and – the focus of this article – thermal runaway protection.

Specific tests are required to determine the behavior of adhesive and labels when exposed to intense heat and/or flames. Flammability properties of materials tested in a horizontal orientation are usually less demanding than those in a vertical orientation. The test method is generally dictated by the rating the material has to meet, which is usually specified by the customer or OEM.

"This article explains horizontal versus vertical burn testing and a third alternative, which specifically applies to our adhesive solutions. "

Flammability testing

The most common and well-known test method for automotive applications is the American FMVSS 302 (Federal Motor Vehicle Safety Standard), with ISO 3795 as the global equivalent. Becoming more prevalent with the introduction of electric vehicles is the UL® 94 test method, created with the intention to classify the burning behavior of plastics used in electric devices and appliances. The next sections will cover both.

Underwriters Laboratories Incorporated Safety Standard UL® 94

The UL® 94 standard describes several variations to the method dictated by the types of materials being tested, their thickness and or rigidity, and their burning characteristics. Some of the variations and resulting ratings correlate with other test standards and ratings.

UL® 94 HB: horizontal burn

The UL® 94 HB method was designed for materials such as untreated polyolefins. Unlike UL® 94 V (see below), this test is performed on specimens in a horizontal orientation. This test is less stringent than the vertical burn test. Results from this method yield a burn rate for a material – that is, how long does it take for material to burn a given distance. In order for a material to be classified HB, it must not have a burn rate exceeding 40 mm per minute over a 75 mm span for specimens having a thickness of 3 to 13 mm, or a burn rate less than 75 mm over a 75 mm span if less than 3 mm thick, and all specimens must cease to burn before reaching 100 mm.

UL® 94 V: vertical burn

This method is used to evaluate solid materials, having a maximum thickness of 12.7 mm, yet rigid enough not to shrink or distort when a flame is applied. Five test specimens for each material, 127 mm long by 12.7 mm wide, are supported in a vertical rather than a horizontal position. A flame from the burner is applied to the bottom of each specimen, held for 10 seconds and then withdrawn until the specimen extinguishes.

The flame is then reapplied for an additional ten seconds. The length of burn or afterglow time is recorded after each flame application. It is noted if any of the specimen drips and ignites a wad of cotton placed below the specimen. A rating of UL® 94 V-0 is the best achievable rating. A material with this rating is considered flame retardant. Labeling materials less than 0.381 mm thick are unlikely to meet the requirements of "V" rating.

UL® 94 VTM: very thin materials

The introduction mentioned a third variation of burn testing. This is a modified method for testing very thin materials that may shrink or distort away from the flame, or are consumed up to the holding clamp due to their thinness. Test specimens are cut to 200 mm by 50 mm.

A mark is made on the outside across the width of the sample, 125 mm from the bottom. The specimens are then tightly wrapped around a 12.7mm mandrel, secured with tape or wire at the top above the 125 mm line. The mandrel is removed and the specimen is secured by a clamp in a vertical position. The method then follows the same procedure as in the "V" protocol. This method is most appropriate for label materials less than 0.254 mm thick and designed with flame retarding features.

FMVSS 302 (ISO 3795): fire retardancy in the automotive industry

Federal Motor Vehicle Safety Standard 302 is a flammability test designed for the automotive industry and is frequently required for materials used inside the passenger compartment and in the engine compartment.

As we discussed above, UL® 94 is the standard for safety or flammability testing of plastic materials for parts in electronic devices and appliances. We would argue that it is far more suited for products such as laptops and smartphones than it is for materials in EV batteries, as it is not included in the scope of the standard. FMVSS 302 tests the burning behavior of materials used inside road vehicles. It is the basis for testing specified by most automotive OEMs and better suited for our solutions.

FMVSS 302 is very similar to UL® 94 HB. A sample is clamped in a horizontally shaped "U" fixture and is exposed to an open flame at one end. The flame is removed and the rate of burn is examined. The burn rate is calculated then expressed as the distance burned over time. A material is usually classified as self-extinguishing if it stops burning in less than 1 minute and the flame has traveled less than 100 mm.

Finding the right approach

UL® 94 dictates that individual components test really well for flame retardancy. Which can in turn lead to a very costly design, development and production process. Given the fact that combining two flame-retardant components doesn’t necessarily lead to a flame-retardant combination, designers, converters and engineers are faced with a challenge when it comes to choosing the right approach.

You can combine two VTM 0-certified materials, a high UL® 94 quality standard for flammability, but that doesn’t automatically result in an VTM O-for the bonded laminate.

To put it another way, a pressure-sensitive adhesive applied anywhere within a car, from seat heating to the design of the battery pack, will never be exposed, but will always be bonded to another material. Meanwhile, FMVSS 302 states that the top 13 mm of anything has to be tested. To quote the standard;

"S4.2 Any portion of a single or composite material which is within 13 mm of the occupant compartment air space shall meet the requirements of S4.3; S4.2.1 Any material that does not adhere to other material(s) at every point of contact shall meet the requirements of S4.3 when tested separately; S4.2.2 Any material that adheres to other materials at every point of contact shall meet the requirements of S4.3 when tested as a composite with the other material(s)."

The perfect partner can help you find the balance you are looking for. The Avery Dennison EV Battery portfolio offers multi-functional solutions that draw from our expansive portfolio of pressure-sensitive tapes and adhesives. Our products meet OEM specifications for a wide range of applications. Beyond bonding means we also welcome the opportunity to collaborate with automotive OEMs and tier suppliers to develop custom solutions that address this and many other challenges. You’ll enjoy access to testing facilities and pressure-sensitive adhesive experts who understand the challenges engineers face. We can work together to produce one-of-a-kind products that give you the advantage you seek.

Find out more about Avery Dennison solutions for thermal protection.

Further reading

About the author

Ulrike Steinfort

Ulrike Steinfort, technical marketing manager for Durable Goods within the Materials Group EMENA, has over 25 years of experience in the durables segment. Her profound knowledge of applications, their requirements, and labeling solutions has been essential in driving durable innovations and developing Avery Dennison’s product portfolio.

Ulrike has formed close collaborative partnerships with customers and end users to help guide them in selecting the correct materials for their applications and provides technical documentation support. She is an expert on compliance topics such as CSA and UL and is a member of the Technical Committee for the UL 969 and UL 969A standards.

With a background in engineering, specifically in paper and plastic processes, Ulrike has a unique understanding of the complexities of the business and a deep understanding of market needs.

ulrike.steinfort@eu.averydennison.com

https://www.linkedin.com/in/uli-steinfort-2191336a